main functions

◆powerful mixing action

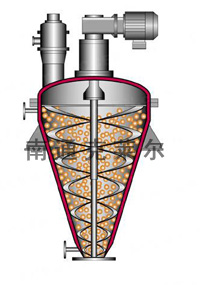

the material near the vessel wall will move up, but the material of center will go downward

◆Rub up and mix flowing materials completely,a mass of materials can be mixed in a short time

◆can realize high standard mixing uniformity

◆almost can discharge all the materials completely

features:

◆Bracket structure,bearing end won’t touch with material

◆The space is very small between mixing propeller and wall of container to avoide of bonding

◆Standard driving box ensure stable movement,low maintenance cost

◆In view of each application ,adopt suitable shaft seal structure,the shaft seals leave product installation , ensure the mixer seals produced by Clare Mixers according to the enterprise standard are used in good conditions.

◆Accordance with GMP design- special O-shape ring of geometry,high quality surface treatment ,eliminate dead angle

available menu:

◆can be designed to vacuumize or operate with pressure

◆can provide cold and hot interlayer

◆Top cover is designed to shell cover according to customer’s requirments

◆sealing device:standard packing seal,framework seal,mechanical seal

◆bleeder valve:ball valve,butterfly valve,gate valve is available

◆Configurable spraying device

◆add shredding mechanism ,can cut up any polymers,to meet the technology requirments

|

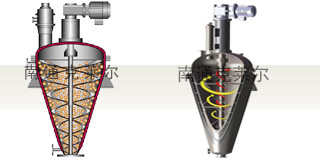

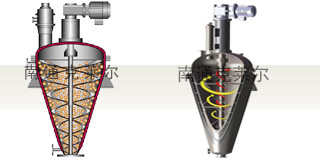

tapered spiral ribbon mixer

internal structure photo of tapered spiral ribbon

scene photograph of tapered spiral ribbon mixer

|

Can satisfy the technological conditions:

1, meet the GMP and FDA standards

2, satisfy the working condition of vacuum, positive pressure, or high temperature operation, when the vacuum or pressure can reach a certain degree and the holding time

3, can avoid vacuum feeding, some light generated when the artificial feeding powder dust float in the sky

4, can be in the process of material mixing for heating or cooling process

5, configuration, CIP online rotating spray cleaning ball, which can be used for cleaning equipment |